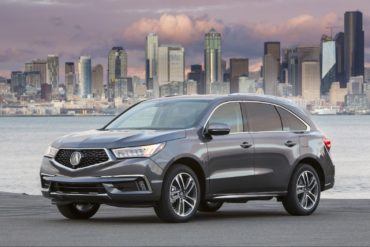

The 2025 Acura MDX has been refreshed to keep pace with other premium machinery, like the Genesis GV80, Lincoln Nautilus, and Volvo XC90.

Acura

Five of the six Acura models sold in North America are made in central Ohio, including the ILX and TLX (Marysville Auto Plant); the RDX and MDX SUVs (East Liberty Auto Plant); and the NSX supercar, which is built to order at the Performance Manufacturing Center in Marysville, Ohio.

In recent times, the Acura Integra Type R has been sought after by Millennial and Generation X collectors.

The 2024 Acura ZDX follows the Honda Prologue as the fruits of a Honda and General Motors partnership that commenced in 2020.

The 2024 Acura TLX is home to numerous improvements after debuting a high-performance TLX Type S PMC Edition for the...

Lest you forget, the first Acura Integra Type R that debuted in 1995 was regarded by many as the best...

The reborn Acura TLX is a breath of fresh air after debuting in 2021. Sporting a redesigned body and underpinnings,...

The cover is officially off the Acura Precision EV Concept, an all-electric SUV that reflects the automaker’s “future design language.”...

The 2022 Acura RDX is part of the Japanese premium automaker’s much-awaited resurgence spearheaded by the fantastic TLX Type S,...

Acura has taken us behind the scenes lately with some cool videos. They have shown us the origins of the Type...

After more than a decade, Acura’s Type S performance line is back and ready to rumble. In this video, Acura...

Like your favorite indie rock bank, after a long hiatus (13 years to be exact), the Acura TLX Type S...

Acura reports its newly redesigned MDX, which boasts an all-new light truck platform, will roll into showrooms on February 2nd,...

Like other all-wheel-drive systems, Acura’s Super-Handling All-Wheel Drive (SH-AWD) distributes engine power to the front and rear wheels. Four spinning...

This would be one of those perfect cars for a Californa pleasure cruise, especially in Long Beach Blue. A reimagined...

It’s not a single element that makes this SUV unique, but the combination of carefully chosen details like a state-of-the-art...

The 2021 Acura TLX is available now for a reasonable starting MSRP of $37,500. Acura went back to the drawing board with...

The 2021 Acura TLX is everything we’re hoping for and more. The second-generation TLX bears no resemblance to the outgoing...

2020 Acura MDX PMC Edition is hand-built in Maryville, Ohio. The MDX PMC Edition has a number of special exterior...

The 2020 Acura MDX cruises into dealerships as of this writing. Buyers can choose between a gasoline or hybrid powertrain. ...

The 2020 Acura RDX is now on the show floor for a starting MSRP under $40,000. Designed and built under...

The Acura TLX PMC Edition is hand-built at the company’s Performance Manufacturing Center. Special exterior color using nano pigment technology...

From nano pigments to powerful engines, the 2020 Acura TLX has a lot going for it. Starting MSRP is fairly...

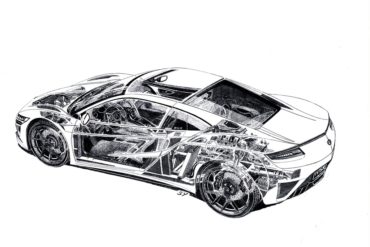

Acura is showcasing a new cutaway sketch of the NSX, hand-drawn by famed automotive illustrator Shin Yoshikawa. Yoshikawa’s cutaways represent, in fine...

The 2019 Acura RDX gets a complete remodel inside and out, giving the compact crossover jazzed-up styling. It sits lower...

The 2019 Acura MDX Sport Hybrid is sitting in showrooms as you read this. Although the term “sport” rankles, the...

The 2019 Acura MDX offers up lots of what current SUV buyers are looking for: room, infotainment gear, safety gadgets,...

Admittedly, we have yet to drive a vehicle – namely the 2018 NSX supercar or RLX Sport Hybrid – with Acura’s...

I bet if you were to ask Acura, they’d say the performance factor never left. But that said, they sure...

The 2018 Acura RLX has arrived with a more simplified lineup and a reduced MSRP for prospective buyers. The RLX...

It’s always exciting when the new 2018 models arrive for our testing. It’s even better when a new sporty model...

Many consumers don’t think of the Acura MDX when searching for a new luxury SUV or crossover, but it’s definitely...