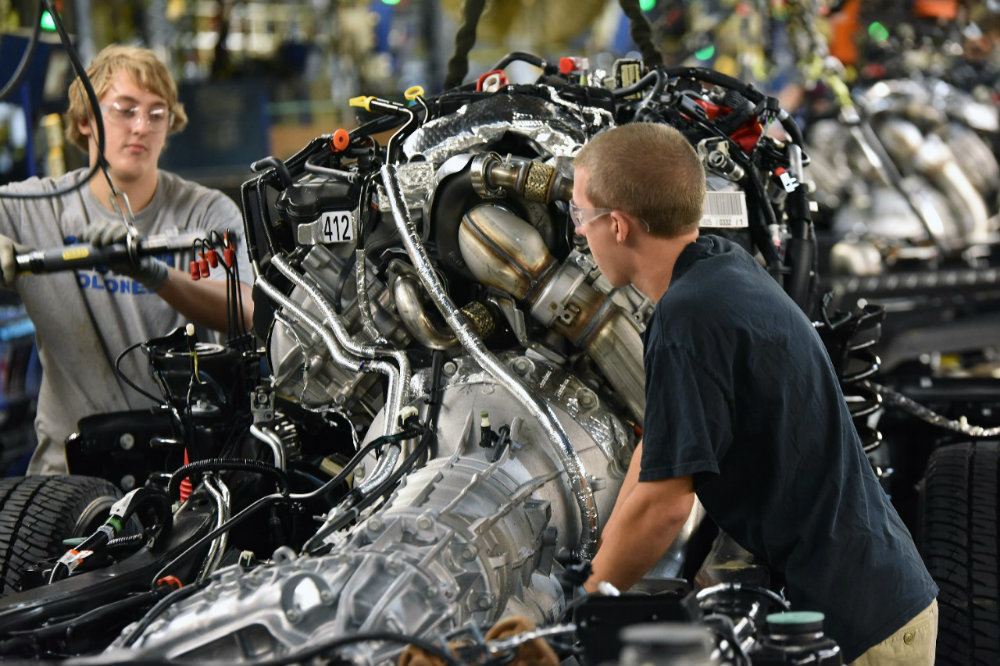

Ford Motor Company is investing $900 million into the Kentucky Truck Plant for upgrades to build the all-new Ford Expedition and Lincoln Navigator. The vehicles will arrive at Ford dealers this fall but also be exported to 55 markets globally, including the Navigator to China. The automaker says this latest investment in Kentucky will help improve the company’s “operational fitness” while building vehicles that “excite customers around the world.”

Core Business

The investment for the Kentucky Truck Plant comes of the heels of another $350 million announced last month for the Livonia Transmission Plant. Ford explained at the time how the investment in Livonia will help fortify their core automotive business, a similar sentiment being echoed with this latest news in Kentucky.

“Large SUVs are attracting a new generation around the world – and we’re finding new ways to deliver the capability, versatility, and technology that customers around the world really want with our all-new Ford Expedition and Lincoln Navigator,” said Joe Hinrichs, Ford Executive Vice President and President, Global Operations.

The Kentucky investment secures 1,000 jobs for hourly workers at the Louisville plant. In 2015, the blue oval dedicated $1.3 billion to the plant for the all-new Super Duty that was forthcoming at the time. That investment resulted in 2,000 new jobs bringing the total at Kentucky Truck to nearly 7,600 workers. While trucks and SUVs represent a significant portion of Ford’s portfolio, it’s not the only thing motivating these strategic investments.

“At the same time, we also have looked at how we can be more successful in the small car segment and deliver even more choices for customers in a way that makes business sense,” Hinrichs explained.

Core Focus

Production of the next-generation Focus begins in the second half of 2019. Most North American Focus variants will initially come from China with other models following out of Europe at a later date. Ford emphasizes not a single U.S. hourly employee will be out of a job regarding the new manufacturing plan for the Focus. Current North American market Focus models are built at the Michigan Assembly Plant and will continue as such until mid-2018. At that time, Michigan Assembly will switch over to Ranger and Bronco production.

“Finding a more cost-effective way to deliver the next Focus program in North America is a better plan, allowing us to redeploy the money we save into areas of growth for the company – especially sport utilities, commercial vehicles, performance vehicles as well as mobility, autonomous vehicles, and electrified vehicles,” Hinrichs said.

The new Focus production initiative saves $1 billion in investment costs versus the original plan – $500 million on top of the $500 million savings announced earlier this year by cancelling an all-new manufacturing facility in San Luis Potosi, Mexico, and moving Focus production to the Hermosillo, Mexico, plant. In light of recent criticisms about Ford’s manufacturing elsewhere on the planet, the blue oval has already invested $12 billion in its U.S. plants, creating nearly 28,000 American jobs in the last five years. Currently, Ford has more hourly workers and builds more vehicles in the U.S. than any other automaker.

Carl Anthony is Managing Editor of Automoblog and resides in Detroit, Michigan.

Photos & Source: Ford Motor Company.