Brakes are a funny thing. If you think about it, cars, especially performance cars, are about going, not stopping. But brakes actually help you go faster; they are not there just to slow you down. Brembo, the Italian brake component manufacturer has known this since day one, and they have been up to some interesting wizardry lately. That wizardry we will see in action as the 2019 Formula 1 season is now underway.

The Science of Stopping

Brakes help you go faster like this: The longer you can stay on the gas, the faster you’re going to go, ergo, if you can use your brakes later and harder, you will, effectively, use them less. Brakes are, essentially, energy transformation devices. Since energy can only be changed, never destroyed, brakes take the kinetic energy of your car traveling forward, turn that kinetic energy into thermal energy, which is then dissipated away into potential energy.

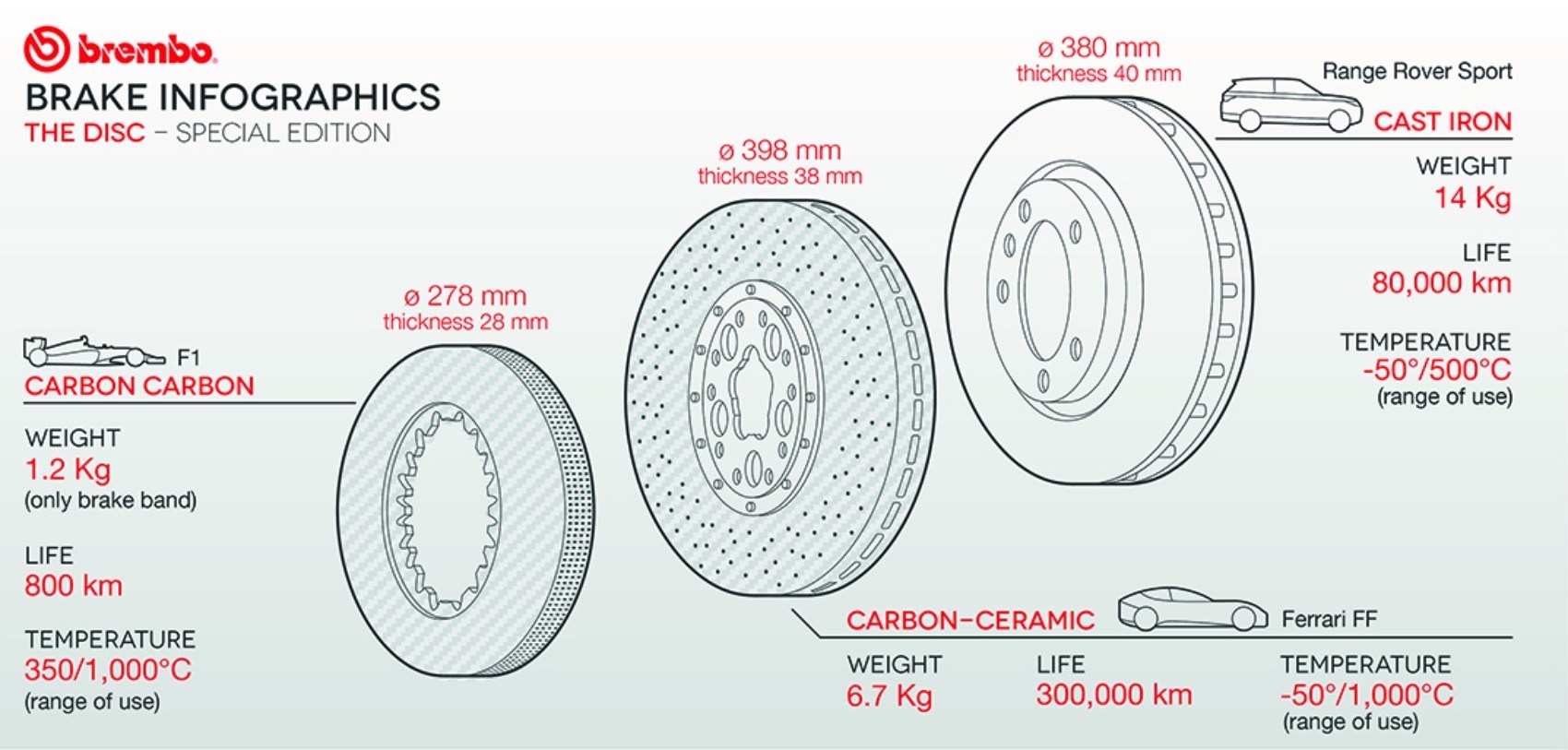

The first designs, drum brakes, have pretty bad thermal efficiency. Disc brakes have much better thermal efficiency, which is why they can stop your car much quicker than drum brakes. Carbon-based brakes have greater thermal efficiency still, so they can stop your car in an even shorter distance. Disc brakes also have the added benefit of being lighter than drums; carbon brakes are even lighter yet, so it’s a paying proposition all the way around.

Brembo has been providing brakes for Formula One cars for 43 seasons. Brembo operates in 15 countries on three continents, with 24 production and business sites, and about 10,000 employees, 10 percent of whom are engineers and product specialists active in R&D. They have multiple championships under their belt (over 300 in Motorsports) and, as you would expect, all that performance goodness makes it to your car, eventually.

Customization Is King

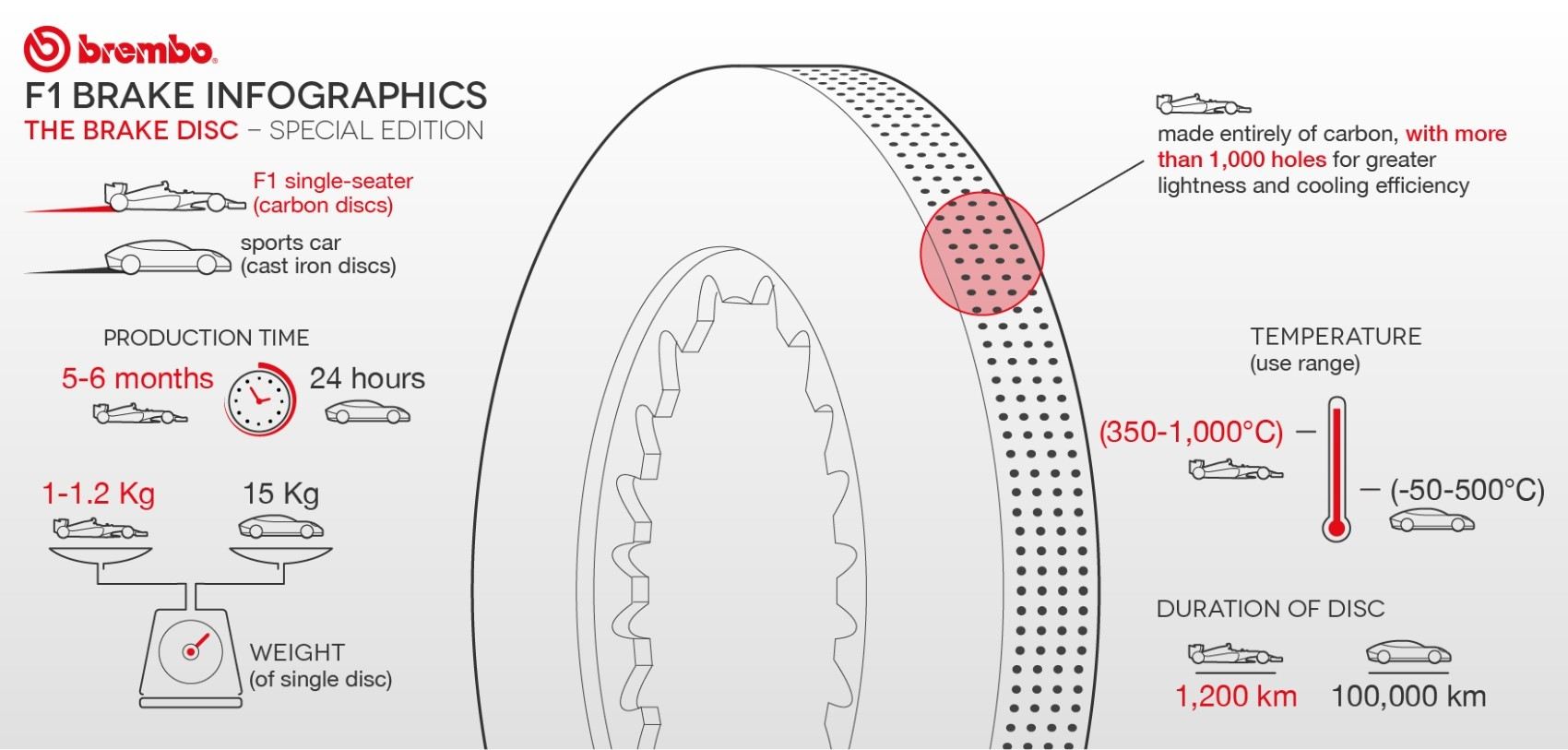

All Formula 1 cars these days use carbon composite brake discs. The discs are made up in a variety of ways. Carbon/carbon matrices, sintered carbon, carbon ceramic, you name it Brembo and their competitors like Lockheed and Hitco and Carbon Industries will go to great lengths to save a gram here and there, or get a few more degrees of temperature. For example, the majority of the cars on the grid for the season-opening Australian Grand Prix were running 32 mm-thick front discs and 28 mm-thick rear discs. That’s actually pretty big, considering a Grand Prix car weighs less than 1,400 lbs.

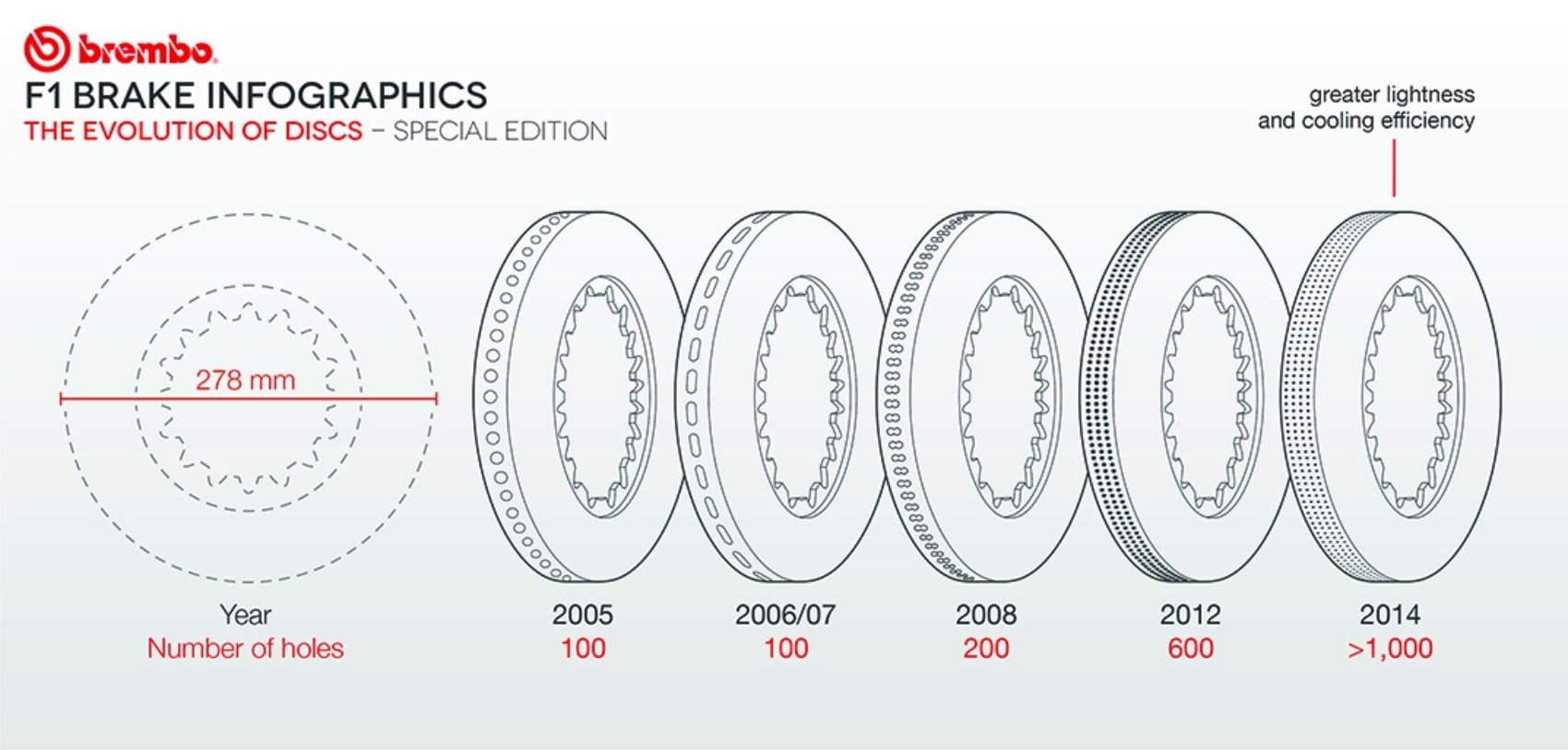

Like everything else in F1, customization is there for the asking. Depending on the temperatures a team expects during a Grand Prix and the given race strategy, each driver has three different options of Brembo discs to choose from. If you don’t want or need much cooling, you can fit your car with Brembo front discs with 800 holes in them. You can also get them with 1,250 holes or 1,480 holes. These holes come in radially, like spokes on a wagon wheel. The disc surface itself is smooth and invariable, allowing the maximum contact area between the brake pads and the disc itself.

Related: Very carefully: how Formula 1 teams move about the planet.

Pizza Ovens & City Blocks

All the cooling is handled by the internal cooling holes, and the carbon material itself. The thermal loads are immense. Carbon racing discs have a designed operating temperature up to 1,000 degrees Celsius. That is more than halfway to turning sand into glass. That’s about four times the temperature of a pizza oven. That is, in a word, hot.

However, given that you have 1,400 lbs. of car entering some corners well in excess of 200 mph; then having to slow it down to around 60 in less than a city block; and then hanging a hard right; well those temperatures start to sound reasonable. And remember: an F1 car does this for every corner; corner after corner for an entire race. It is an immense amount of kinetic energy to dissipate all at once.

Aluminum-Lithium Alloy: Trial By Fire

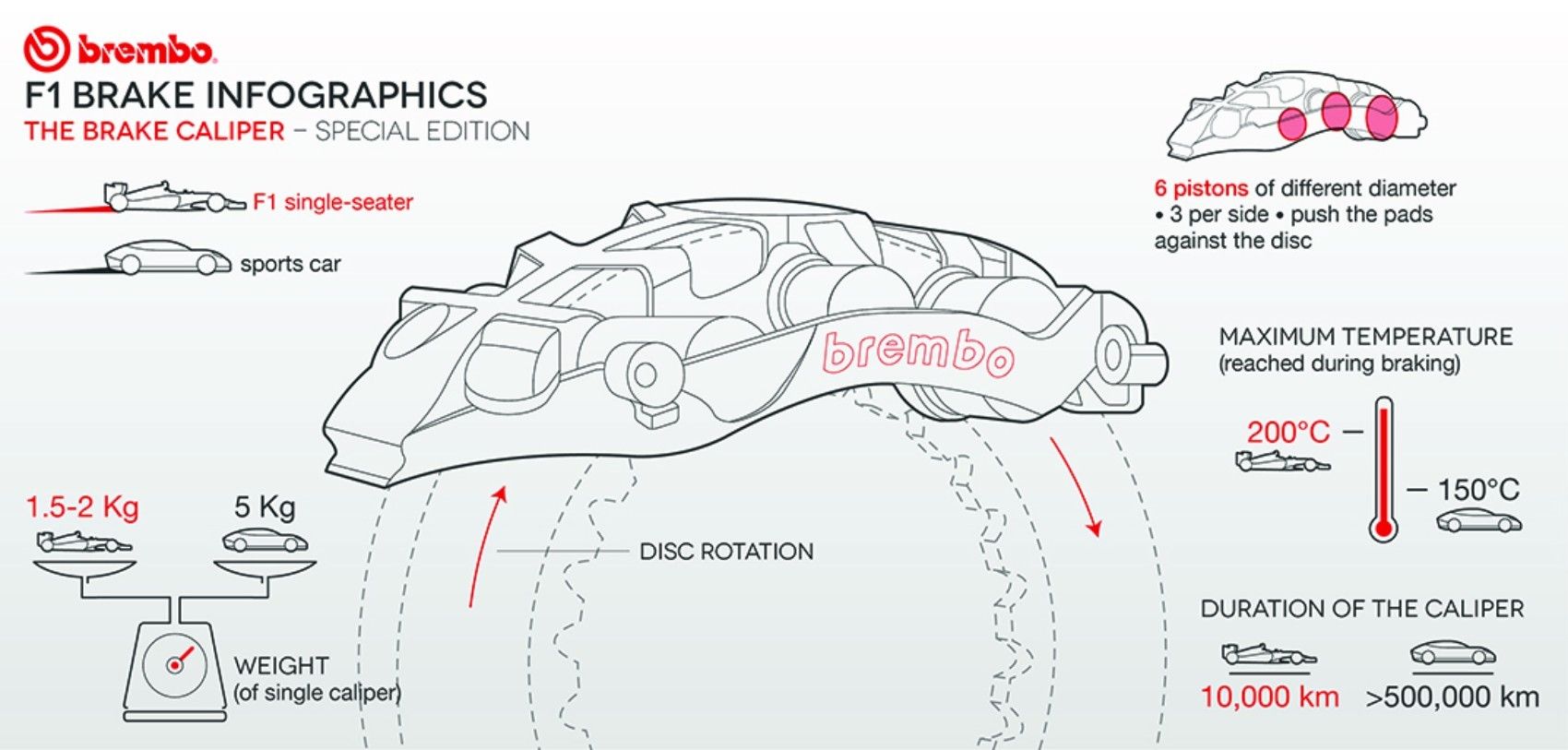

The Brembo brakes on these Formula 1 cars face a literal trial by fire even though they weigh only three to four lbs. This pursuit of lightness and durability extends to the calipers too, and Brembo has some new and very interesting tricks up their sleeve. They made the physical components as small as possible, but go further by making the calipers from aluminum-lithium alloy.

Aluminum-lithium alloy has been a holy grail for material engineers for a while now. Back in the late 80s, aerospace companies first started experimenting with it. Since lithium is the lightest metal out there (ringing it at #3 on the periodic chart – the only stuff that’s lighter is hydrogen and helium, and those aren’t even solid), if you could figure out how to combine it with other metals in an alloy, you would instantly get a huge weight savings.

There are, of course, downsides.

It’s a bear to manufacture, it’s a pain to machine, and it costs a lot. Hey, that $600 million a year budget for these teams has got to go somewhere. Anyway, Brembo is now supplying six-piston aluminum-lithium brake calipers to anyone who wants them. Turns out, seven out of the ten F1 teams decided to go this route.

[bctt tweet=”The @BremboBrakes on these @F1 #cars face a literal trial by fire even though they weigh only three to four lbs.” username=”Automoblog”]

Ground Down To Dust

Each team orders from 10 to 15 sets of Brembo calipers per year on average. This gives you a proper amount of spares over the season, but generally speaking, the calipers themselves don’t wear out very fast, even though they are operating at a temp just shy of your oven: 392°F (200°C).

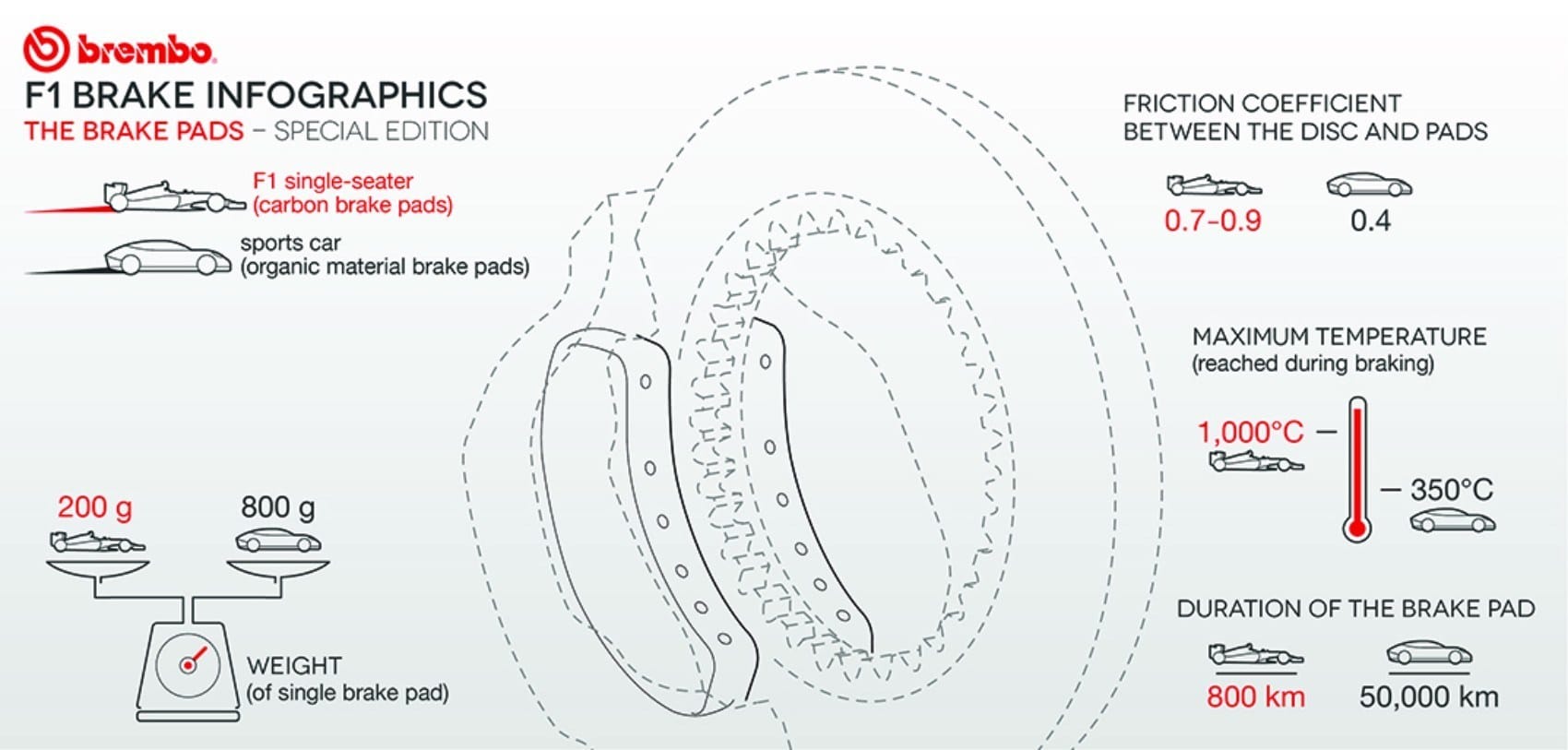

The pads and discs themselves are a whole different matter. They work amazingly well, but for an amazingly short time. Both are completely used up by the end of a 200-mile race. The pads are ground down into dust and the discs are ablated down to nearly their cooling holes. Running the brakes too hard can literally destroy the discs, rendering them into a form that looks like black string cheese, if not outright exploding. During a season, Brembo supplies each team between 150 and 300 discs and up to 600 brake pad sets.

No, that is not cheap either, with a full set of discs and pads running around $15,000 per car.

But, like F1 champion Graham Hill famously said, “Speed equals money sir. How fast do you care to go?”

Tony Borroz has spent his entire life racing antique and sports cars. He is the author of Bricks & Bones: The Endearing Legacy and Nitty-Gritty Phenomenon of The Indy 500, available in paperback or Kindle format. Follow his work on Twitter: @TonyBorroz.

Brembo Formula 1 Infographics

These graphics illustrate the main components of the Brembo brake systems used in Formula 1. Each graphic is accompanied by a more detailed technical description from Brembo, which can be found here.

Brake Discs

Brake Pads

Evolution of Discs

Carbon Ceramic Brake Discs

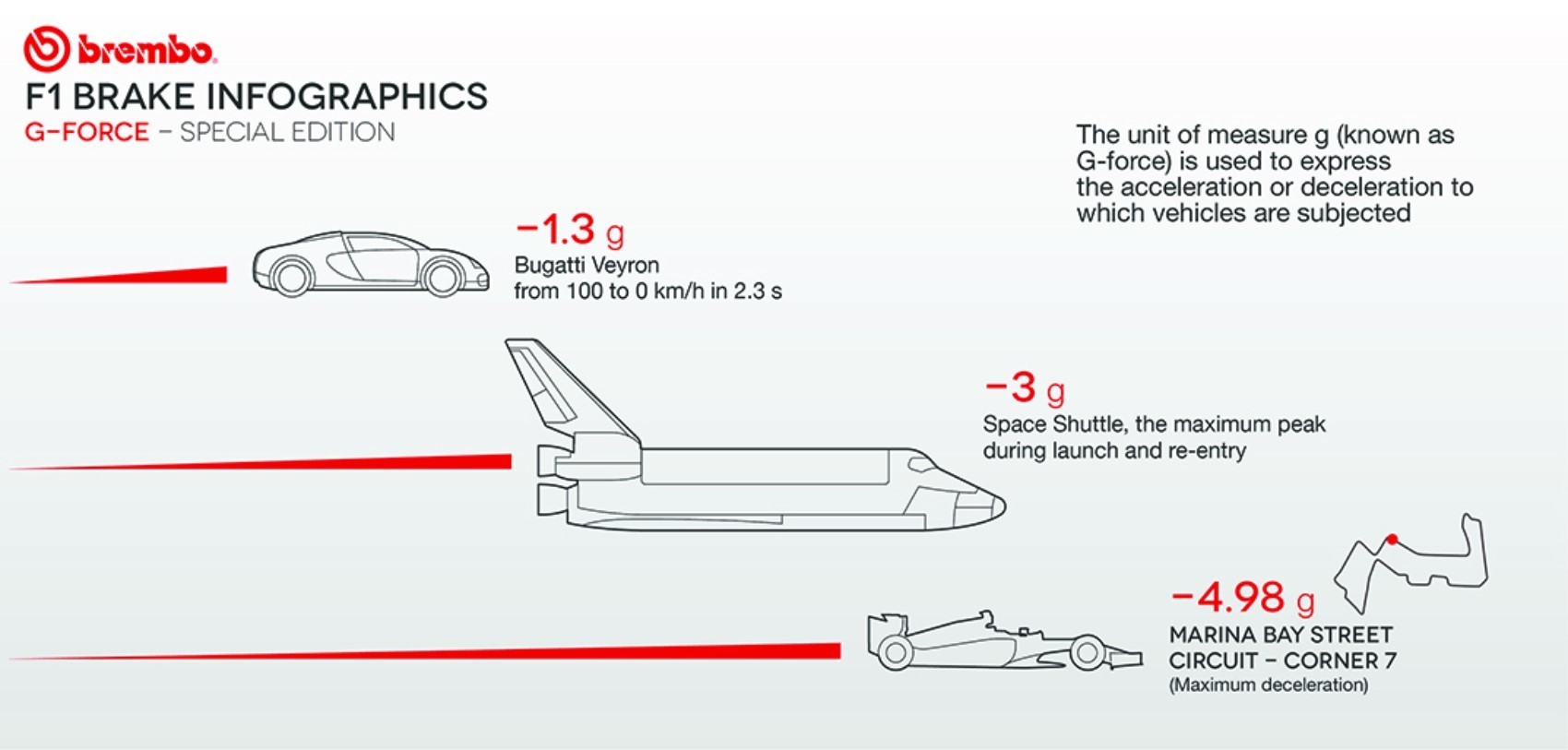

G-Force

Photos: Brembo SpA, Ferrari S.p.A.

Infographics: Brembo SpA.